GrowSave recently held conversations with two companies with very different approaches to integrating solar photovoltaic (PV) panels with horticulture: Polysolar and Voltiris. This blog highlights outcomes from these conversations and information from shared case studies.

Polysolar:

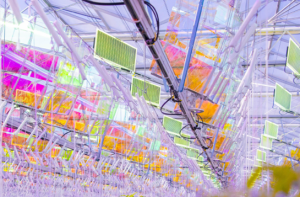

Polysolar’s approach to agrivoltaics uses lightweight flexible panels to integrate into systems where regular panels would otherwise not be possible. By spacing the panels as shown in the image, the system minimises shading to the plants underneath.

Their lightweight flexible panels have a weight of 2.4 kg/m2, efficiency of 18.3%, and power density of 180 W/m2. For reference, typical crystalline-silicon panels have weight around 12 kg/m2, efficiency around 22%, and power density around 220 W/m2. The table below shows what this means for a medium-sized 100 kW system:

| Panel Type | System Capacity | Area Covered | Weight |

| Lightweight Flexible | 100 kW | 556 m2 | 1,333 kg |

| Crystalline-silicon | 100 kW | 455 m2 | 5,455 kg |

In theory, since these two systems have the same capacity, they should generate the same volume of energy per year. However, the flexible panels by their nature cannot be wholly South-facing, which will make their annual generation more in-line with an East-West or North-South roof-mounted crystalline-silicon system.

The image above is from the Electric Berry project, which Polysolar conducted in collaboration with the University of Greenwich and Hugh Lowe Farms, evaluating:

- Effects on photosynthesis, biomass production, and nutritional profile

- Temperature regulation within the polytunnel due to strategic shading

- Overall yield and crop quality

- Financial viability and scalability for wider farm use

The project spanned two years, and integrated PV generation with on-site irrigation, robotic systems, and crop monitoring, utilising energy storage batteries to make best use of the generation.

Results are not yet public, but the potential for this kind of system is high in the soft fruit sector.

Voltiris:

Voltiris’s approach fits inside a commercial greenhouse, and their systems comprise of two parts: infrared (IR) reflectors and PV panels. These reflectors transmit most of the light spectrum, reflecting only the IR wavelengths onto the panels themselves and allowing for relatively few shade-causing opaque panels. The reflectors are programmed to follow the path of the sun to ensure high rate of capture of the IR radiation.

Several testing and pilot installations are spread across Europe, and the potential capacity for these systems is 260 kW per hectare. To enable this, approximately 1.2 m of clearance is needed above the top of the plants.

Since the system is designed to make use of IR, this presents an interesting additional benefit for these systems. When growing strawberries under a Voltiris system, a difference in peak plant temperature of 5°C was observed. Similar results were seen on tomato and pepper crops.

This has potential to reduce the use of shade screens for temperature control, maintaining CO2 levels, thereby potentially increasing yields. Throughout this trial, the strawberries under Voltiris produced between 7-24% more class 1 fruits across two varieties, and an average of 4% higher yield across all classes and varieties. Peppers saw similar results, with a 6.3% increase in class 1 fruits under Voltiris, compared to a control.

Purely from an electricity production perspective, Voltiris model payback periods under ten years, depending on energy contracts. If agronomical benefits can also be consistently achieved, these systems become even more attractive.