First published November 2019

If you want to convert a glasshouse to grow soft fruit successfully you need to take account of the age of the glass, what was grown previously, existing equipment, your specific growing season and the need for appropriate ventilation.

Back to: How to use glasshouses for soft fruit production

How old is the glass?

For many reasons, the age of the glass may be a determining factor for the suitability of the structure for modern soft fruit production. They include:

- Old glass may not be economic to heat for extended season production. For example, the build-up of moss etc. in glazing bars and on glass decreases light transmission, causes heat loss and water ingress. Ill-fitting doors are also energy inefficient.

- In the past, there were several long-established UK glasshouse manufacturers (such as Frampton Ferguson and Cambridge) who built a wide range of multi-span design types and bay widths as well as single-span widespan houses. Glasshouses of this type are likely to have been built in the 1960s and 1970s and will almost certainly require extensive refurbishment. Locating spares may also be troublesome.

- Most glasshouse design over the last 30 years has focussed on the Venlo principle, which features standard bay widths such as 3.2m, 4.0m and multiples thereof.

- Older Venlo glasshouses may well be fitted with inefficient ‘pram-handle’ vents, which do not easily lend themselves to the deployment of thermal screens.

- In the past, many glasshouses had a lower post height than the 5-6m that is normal now. Low post height will adversely affect the climate in the crop because of the lower volume of air and may be less efficient ergonomically for crop work. The higher summer temperatures in low structures can have a severe effect on crop production.

- Expert advice should be sought before installing screens or crop gutters in old glass, since older structures may not be able to support the additional stresses resulting.

- Older structures may not qualify for full insurance, especially for snow loading.

What crop was grown previously?

- Glasshouses previously used for lettuce production will have only basic heating and overhead irrigation, so will need to be completely fitted out for soft fruit.

- Ornamentals production systems vary widely. Structures previously used for bedding may only have heating systems designed for frost protection, such as indirect air heaters for direct fired Priva-type heaters.

- The existing irrigation for ornamentals is unlikely to be suitable for strawberry production. Benches or tables, if installed, will need to be removed.

- Glass previously used for long-season salad crops such as tomatoes and cucumbers will already have much of the infrastructure and equipment required for soft fruit production and will generally be a Venlo design with standard dimensions.

- Depending on bay width, extra crop rows for strawberry production may be possible or desirable. For example, in tomato production, it is normal to plant five crop rows in an 8m span; in strawberries, the most space efficient density is to plant seven crop rows (or eight rows when moveable gutters have been installed).

- If the previous crop was grown on gutters, there could be several issues. Gutter design tends to be crop specific, so gutters for tomatoes or cucumbers are not ideal for strawberry production. Growers have been known to turn gutters upside down for use with strawberries, but since only one side of the gutter is usually coated, using the flip side may result in some contamination of the irrigation runoff with zinc. Gutters for strawberry production are usually fitted with extra bracketing for fruit tape and wire to ensure good exposure to available light and presentation of the fruit for harvest.

What existing equipment is installed?

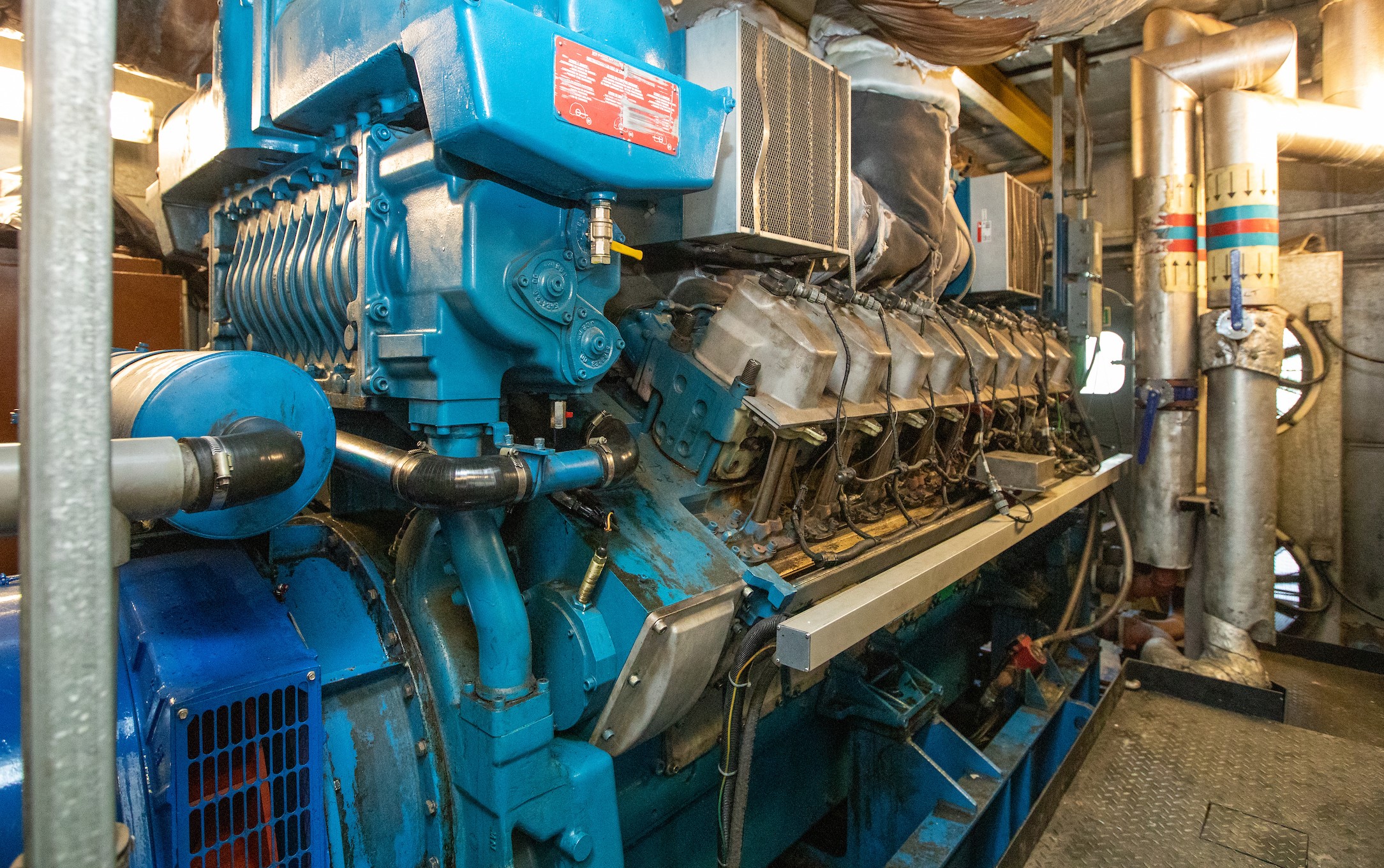

Conversion costs for heating systems originally designed for other crops will depend on several considerations, not least budget.

- An ‘ideal’ heating system for soft fruit production will utilise as much of the existing system as possible – with few, if any, changes in the boiler house or to pumps and mixing valves.

- The number and position of ground level pipe rails will usually have to be adjusted to suit table-tops or gutters and additional crop rows.

- A grow tube for additional root zone heating under each crop row is highly recommended.

- In the cases, where the existing irrigation system is to be re-used, it will be necessary to install extra irrigation lines and drippers.

- Existing CO2 distribution pipework can often be re-used, with extra lines installed for additional crop rows. (It is essential that the CO2 distribution system has been professionally designed in the first place, to ensure the correct spacing of outlets and uniform pressure! If unsure, ask for a specialist opinion.)

What is your anticipated growing season?

Typically, strawberries grown under glass will start production in April through to June and again from mid-September until November or early December. Extending the season earlier and later will require more heat, which will almost certainly be uneconomic without a modern structure with an efficient heating system, climate control and energy screens.

Make sure you have good air circulation

Whatever the age or level of the fitted equipment, achieving an even climate throughout the glasshouse is a key factor in modern protected cropping, affecting all other aspects of climate. Good air circulation is a crucial component in achieving an even climate. Where existing air circulation fans are installed, they should be re-used, but bear in mind a growing promotion over the use of vertical fans (i.e. fans which move air vertically rather than horizontally), especially for table-top and gutter production.