First published February 2020

Learn what types of sensors are best suited to your needs, how to use them and how to manage and use the data they produce effectively.

Quick links:

- Make the most of cheaper and easier data collection

- How to measure temperature

- How to measure air movement, humidity, and radiation

- Wired vs wireless sensors

- The impact of big data

Make the most of cheaper and easier data collection

The use of sensors within horticulture is hardly a recent development, with thermometers, measuring boxes and CO2 sensors having been used for decades. However, the advent of wireless sensing technology, as well as the reduction in prices of such equipment, means data collection is now cheaper and easier than ever before.

Determining which types of sensors are best suited to your needs depends on a myriad of factors. Like it or loathe it, technology is here to help.

This update looks at the sensors that may be available to you for different measurement requirements, how the information may be shared and viewed, and the impact of big data.

The first step in considering the types of sensor and how to handle the data is to decide what you are trying to measure and what the available options are.

How to measure temperature

Consider what type of temperature sensor setup best suits your crop and how you might benefit from the added insights possible from thermal imaging.

Temperature data is often the primary factor on which the glasshouse climate is controlled. However, it is also important to consider what temperature is being measured and whether this is what you intend. Consider the effects of measuring – and controlling on – each of the following:

- Glasshouse air above the crop

- Air at crop level

- Plant leaf

- Flower/fruit

A grower’s perception of the environment upon entering a glasshouse is likely to be based on feel, with part of that being air temperature. However, depending on what is being grown, the temperature of the ambient air could be quite different from what the crop is experiencing. Physics tells us that cold air sinks, while warm air rises; consider how this would affect a ground-level ornamentals crop compared to a tall vine crop.

If you have a relatively conventional setup with just one or two temperature sensors per compartment, the chances are there’s room for improvement. By controlling your heating system based on just a couple of measurement points, there may be hot or cold spots and, therefore, entirely different growing conditions within the crop. This could be caused by several factors, but ultimately can lead to uneven crop production. Instead, you might consider a matrix of sensors to create a heat map, allowing you to pinpoint problem areas.

The benefits of thermal imaging

Good temperature control is crucial; however, standard temperature sensors can be somewhat limited, usually only measuring the temperature of the air around them and not that of a specific object. This is where thermal imaging or infrared cameras can come into their own, allowing surface (e.g. leaf or fruit) temperatures to be measured. Depending on the growing conditions and the energy balance of the plant, this can highlight potential health risks.

The visual nature of thermal imaging means temperature differences and unevenness in the climate can be identified more easily than by using a table of numbers alone.

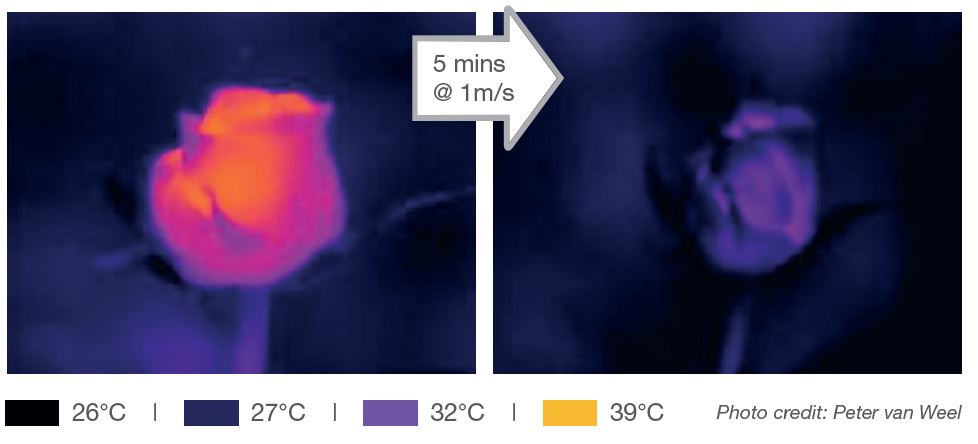

It is this visualisation that can help with understanding what is going on and how the crop reacts under different conditions, which may be very different from an initial perception. Interpretation of a thermal image should be relatively straightforward, but when and how to react is down to the grower and his or her knowledge of what the plant can tolerate without adverse effects. For example, consider the image of a rose flower as shown in Figure 1.

The thermal image on the left shows a rose flower approaching 39°C while the rest of the plant and the ambient air are much cooler. This is the plant’s way of trying to expel excess energy and demonstrates an imbalance in the growing environment. Such high temperatures can be damaging to the plant but without a thermal image, it would be very difficult to identify such issues until any long-term impact is demonstrated by the plant, by which time it is too late to remedy. However, using thermal imaging in conjunction with other sensors, such as those measuring incoming and outgoing radiation, it is possible to prevent these problems arising, but only if the climate is controlled effectively on the incoming data.

This highlights the importance of good air movement. By using effective temperature measurement to identify problem areas, these can be rectified fairly easily with some simple air movement strategies. After just five minutes of air movement at 1m/s, the same flower was reduced to a temperature of around 30°C (image on the right in Figure 1), in line with the surrounding climate.

How to measure air movement, humidity, and radiation

Learn what other measurements are needed to achieve an even climate and how to set up and manage these measurements of air movement, humidity and radiation.

Air movement

Not only is air movement vital to ensure moisture is moved away from a transpiring plant, but also to maintain an even temperature throughout the whole growing area. While devices for measuring airflow do exist, e.g. anemometers, achieving meaningful measurements at an acceptable cost is often a stumbling block.

Instead, it may be better to take a proxy measurement (i.e. to measure something else), such as temperature, and to infer air movement based on the results for uniformity. If, for example, by measuring the temperature at several locations in the glasshouse you see a large variation horizontally and/or vertically, this suggests insufficient air movement to maintain a homogeneous climate.

Humidity

Most growers will be familiar with a standard measuring box, containing a wet bulb and a dry bulb. These do a good job of measuring humidity levels, providing they are well-maintained, regularly calibrated and are in a suitable location. When combined with temperature, the data can be used to determine Relative Humidity (RH), Absolute Humidity (AH) and Humidity Deficit (HD). Each is useful in its own right, so it is worth understanding these terms and how to control your climate based on the different measurements.

As with temperature, measuring just a couple of locations within a large area isn’t enough to guarantee an even climate. For example, if the crop is transpiring, it is important to make sure the moisture is moved away from the plant. Good air movement can help to achieve this, but don’t leave it to guesswork. A well-placed measuring box at crop level and away from any external influencing factors, such as fans or heaters, will give the best indication of what the crop is experiencing.

Radiation

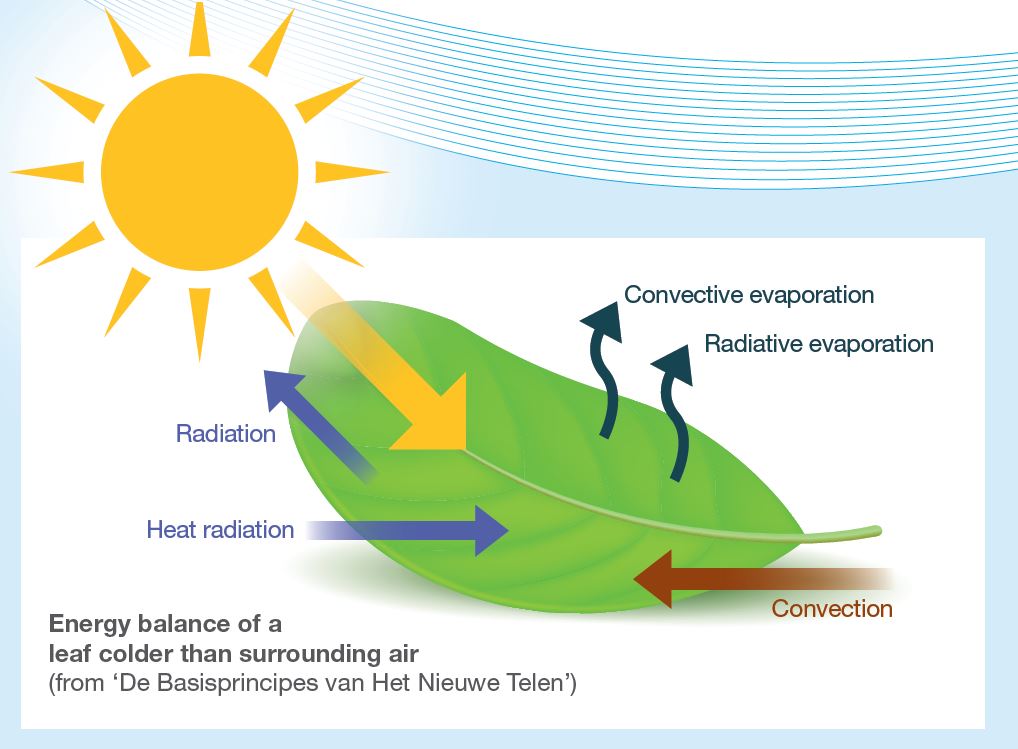

Rather than thinking in terms of light alone, a better approach might be to measure net radiation. Radiation is the transfer of energy from one body to another, such as from the sun to a plant or from a plant to a clear sky. Importantly, radiation is both incoming and outgoing and can be measured using a pyranometer and pyrgeometer respectively. It’s quite possible that when there is a clear sky on a winter’s day, there is a net loss of radiation from the glasshouse.

In such instances, it may be more cost-effective to keep thermal screens closed, thus adding a layer of insulation, reducing heat loss and providing a barrier to outgoing radiation.

By measuring the energy entering and leaving the glasshouse and by using screens effectively, considerable energy and financial savings are possible. For optimum energy saving, keep screens closed until the incoming radiation at least matches what is outgoing.

Wired vs wireless sensors

What are the factors to consider when deciding between wired and wireless sensors, including when you want to move sensors around the glasshouse.

When deciding between wired and wireless sensors, there are a few things to consider:

- Will it work with your existing climate computer?

- Will you be moving the sensors from one area to another over time?

- How many sensors do you need to give enough data to be meaningful?

- What is the cost/benefit of the additional data?

Several companies offer wireless sensors but make sure you check if they will work with your existing setup, or if you will also require additional hardware and/or software to collect and analyse the data. Any one-off or recurring costs should be factored in and evaluated against the benefit of the additional data. Improved crop quality or yield may be a strong argument to invest.

Wireless sensors come into their own when you want to move them around. Rather than having to set up sensors across the whole growing area, you might instead choose to have a few that can be moved around. Although this won’t allow real-time comparisons between different areas, it can still be useful for highlighting trends or problems.

The impact of big data

What you need to know in order to make the most of the amount of data it’s now possible to collect and how to manage both the data and the cost of acquiring the data effectively.

The availability of low-cost sensors provides an opportunity to potentially revolutionise data collection in horticulture. No longer are growers limited to just one or two measurement points within a glasshouse. Most modern climate computers will accept third party sensors and make data collection relatively simple. Furthermore, smartphone apps now free the user from the climate computer itself, allowing real-time monitoring from anywhere in the world with an internet connection.

The collection of data is all well and good but is completely pointless unless you:

- Understand what it means;

- Can control your glasshouse climate accordingly.

For example, while a large matrix of temperature sensors giving hundreds of individual measurements may highlight problem areas. It is of little use if you can only control the heating system for the whole area – i.e. the level of control should be in line with the number of data points.

Therefore, it’s important to find the balance between having enough sensors to give a good resolution of the climate and enough control over different zones to be able to react as necessary. Another benefit of data collection is the ability to analyse trends over time and optimise accordingly.

Data management

Storing your data is an essential part of the process and should not be overlooked. Your existing climate computer may be able to handle the incoming data but beware of its limitations. The number of inputs and the amount of data storage could become limiting factors. Consider also the usability of the data analysis interface, does it allow you to evaluate your data effectively and easily?

Several sensor manufacturers also offer their own data management platforms; they are often designed to integrate well with a range of hardware and to be user-friendly. Importantly, they consolidate all your data in one place, making analysis easier.

Data sharing

Proponents of Next Generation Growing (NGG) have often advocated the benefits of data sharing. While this can be an uncomfortable step for some, others have found that being able to view and analyse the growing strategies of their peers has helped them develop their methods. A collaborative approach to growing, even between neighbours and those competing for the same markets, can be mutually beneficial.

This approach was trialled with a GrowSave study group. The project aimed to implement NGG techniques, which saw some of the group make significant changes to their growing strategies. Through using an online platform, the group shared climate data among themselves and with a crop consultant. This larger pool of data could be used to identify which strategies work well, allowing growers to iteratively refine their methods.

Cost

It is almost impossible to provide a comparison of the indicative costs of a range of wired and wireless sensors. This is because so much depends on your existing data acquisition infrastructure and how seamlessly you would like the data to be integrated into your climate control computer.

Many simple sensors can be had for a few pence (such as thermistors), whilst more complicated bespoke sensors designed for a glasshouse environment will cost upwards of £100 each. Operating and acquiring the data may require additional cable installations and input/output modules where wired systems are being extended, or the purchase of wireless repeaters, internet connectivity and data subscription contracts if operating independently and directly to the internet.

It is also worth considering sensor quality, both in terms of accuracy and longevity in the target environment, as well as ease of maintenance and calibration. Always check the calibration guidelines before purchasing; if a sensor has to be sent back to the manufacturer, for instance, this can be costly and leave you without any data in the meantime. Ideally, sensors will be easily maintainable by the end user. It may be worth investing in better quality sensors, costing more upfront but saving time and hassle further down the line.

With the availability of so much data, managing it all must be given serious thought. While it can be possible to use existing hardware and software to analyse data, it may be worth considering a bespoke package or using one of the third-party tools out there. However, these options often come at a cost, usually in the form of a monthly or annual subscription and on a ‘per sensor’ or data volume basis.

As with all purchasing decisions, it pays to understand what you require and get several indicative quotes from suppliers before committing to purchase.

Note costs correct as at August 2019.

You might also like: How to choose and look after sensors in glasshouses:

Sensors are fundamental to the effective control of the glasshouse environment. Learn what to look out for to avoid inaccurate measurements which can result in wasted energy and poor crop performance.