Biomass combustion is relatively common, however, there has been an increasing interest in other thermochemical conversion methods, which offer more varied outputs: combustible gases, oils, and organic carbon (char). With the right system design, reactors can support on-site heat and power generation, carbon sequestration, and production of oils and solids which can be sold into industrial sectors for additional revenue.

Biomass Conversion

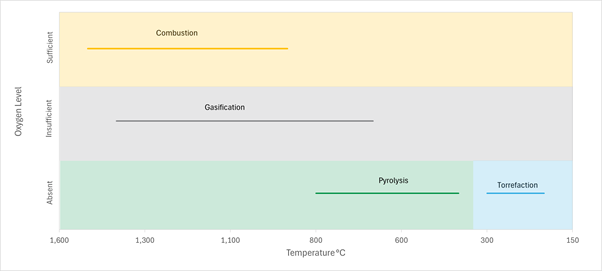

The different types of biomass thermochemical conversion are on a scale of temperature and available oxygen:

Given sufficient levels of oxygen and heat, biomass is ignited and combusts. This reaction is exothermic, meaning that heat is released. The released heat is enough for combustion to be self-sustaining. The other outputs of complete combustion are carbon dioxide and ash.

Each of the other types of conversion are endothermic, meaning they require a constant heat input.

Gasification occurs over a similar temperature range and with a limited supply of oxygen, insufficient for combustion to occur. Instead, heat and the small amount of oxygen react with biomass to produce syngas, a mixture consisting mainly of hydrogen and carbon monoxide gas. Syngas is an effective combustion fuel, burning more cleanly and efficiently than biomass. It is often used as boiler/CHP fuel.

Pyrolysis occurs within a lower temperature range, between 400-800°C, and with no oxygen present. There are three resultant products: syngas, bio-oil, and char. Depending on the temperature, residence time, heating rate, and fuel particle size, the relative quantities of these three outputs can be adjusted. Fast pyrolysis uses higher temperatures and maximises liquid yields, whereas slow pyrolysis uses lower temperatures and prefers solid yields.

Bio-oil is a dense complex mixture of oxygenated hydrocarbons and water. The aqueous phase can be separated from the oils and is colloquially known as ‘wood vinegar’, which is highly acidic and has various uses as a pH regulator and pesticide. The remaining oils are of low quality, with calorific value around 50-70% of petroleum-based oils. It can be upgraded and used to substitute heavy fuel oil or transport fuels, combusted to produce heat and electricity, or refined further for use in the chemical industry, for example, bioplastics manufacturing and hydrogen production.

Char, sometimes called biochar, is very similar to charcoal. In fact, charcoal kilns are ancient rudimentary pyrolysis reactors. However, the advancements in controlling and optimising the pyrolysis reaction have led to a superior product. Biochar has a very high porosity, containing millions of tiny holes which are produced as high temperature gases escape from the biomass feedstock. This structure is key to the usefulness of char, which has applications in filtration, construction, and as a soil amendment improving water and nutrient retention. Since it is comprised of inert carbon, its production can remove carbon dioxide from the carbon cycle, actively sequestering it.

Finally, torrefaction is a type of pyrolysis which occurs at even lower temperatures, between 200-300 degrees Celsius. This reaction is designed to maximise char production.

Application

In a horticultural setting, the first thing to consider for pyrolysis is the feedstock. High quality wood pellets will produce the highest quality char, and the overall efficiency of the reaction (total energy in vs useful energy out) will be better for drier feedstock. However, systems exist which make use of waste material such as spent (organic) growing media and plant residues.

Other than heat, electricity, and CO2 – which are all useful outputs from pyrolysis and combustion of the resulting products – biochar has a lot of potential both to sell into other markets, and as a soil amendment. When mixing into soil, biochar improves the water and nutrient retention. Thanks to these properties, it has potential use as a replacement for peat in growing media.

The replacement of peat is a particularly exciting application which would make a significant impact on the sustainability/carbon balance of ornamental operations. This is particularly important considering speculated bans on peat-based growing media.

Pyrolysis on a commercial scale is very uncommon in the UK and so there is potential that a novel application is eligible for grant funding. For assistance in grant funding opportunities, or a detailed technical study into pyrolysis on your site, contact us here: growsave@nfuenergy.co.uk